Manufacturers are striving to achieve better visibility into their daily operations, from sourcing and design to factory operations and the various departments involved. They are taking steps to modernize their operations with infusion technologies such as digital twin, the internet of things (IoT), 6G, 5G, cognitive robotics, artificial intelligence (AI), machine learning (ML), and digital thread and standardization of enterprise resource planning (ERP) and manufacturing execution systems (MES) to achieve operational clarity. At the same time, manufacturers are working to make the supply chain more resilient and adopt sustainability practices with evolving regulatory and compliance requirements to create a well-rounded, sustainable manufacturing value chain. Manufacturers are looking to drive digital transformation with a consistent focus on efficiency and building resilience across the value chain.

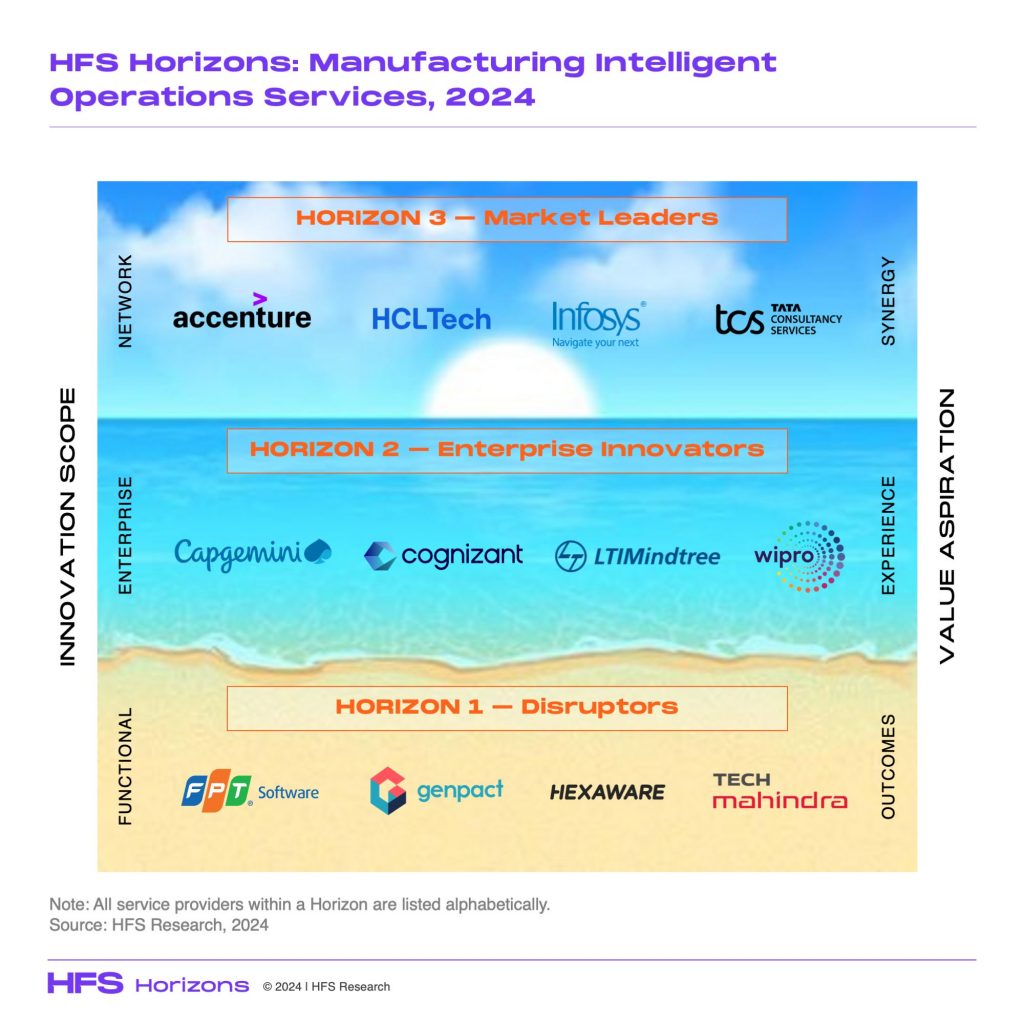

HFS’s newly published Manufacturing Intelligent Operations Services report explores the capabilities of the industry-leading service providers, enabling manufacturers to achieve their goal of autonomous manufacturing and sustainable practices, making operations efficient and resilient.

Exhibit 1: Manufacturing Intelligent Operations Services Report, 2024, evaluates the capabilities of the 12 service providers across the horizons

Strengthening the foundation for intelligent manufacturing with data and technology collaboration

To achieve the goal of integrated manufacturing processes, establishing a data-driven business model is essential. Manufacturers must put data at the heart of their operations, going beyond simply regular reporting. Manufacturers need to integrate data from across functions, breaking the silos to optimize shop-floor operations and drive innovation and real-time decision-making. Thus, the convergence of information technology (IT) and operational technology (OT) has become crucial in gaining access to comprehensive real-time data for better decision-making and assessment of processes on the shop floor.

Real-time data from the convergence of IT and OT also enables the seamless implementation of digital twin and digital thread, creating a connected ecosystem. Digital twin enables all involved stakeholders to visualize a digital replica of an operational asset or manufacturing facility. It creates a unified environment that helps to eliminate silos while enabling data centralization from multiple sources, such as sensors, machinery, and enterprise systems. And digital thread helps to establish traceability and connect data throughout the manufacturing lifecycle. Together they break down communication silos and establish a continuous loop across the manufacturing value chain.

It is crucial to bridge the IT and OT divide to create a data-driven culture, support technology transformation, and enable real-time visibility into end-to-end shop floor operations. Service providers are supporting manufacturers in driving collaboration between IT and OT data by integrating unified digital platforms to increase operational efficiency.

Building partner ecosystem to enhance capabilities and drive innovation

Service providers are building robust partnerships and strategic alliances to build a strong delivery ecosystem that supports evolving customer requirements and constantly changing market dynamics. Service providers are building alliances with niche players, hyperscalers, startups, industry bodies, and academia to drive innovation, foster digital capabilities, and deliver value to clients. This not only enables them to build innovative solutions around emerging technologies but also to leverage a vast pool of talent in driving digital transformation. This establishes that service providers are continuously aiming to evolve with the rapidly changing industry and customer demands and requirements and tap into new growth opportunities.

Resilient supply chains and sustainability are becoming key priorities

With supply chain challenges causing recent disruptions, manufacturers are increasing investments to gain supply-chain visibility. Simultaneously, increasing regulatory pressure is driving manufacturers to adopt circular economy and decarbonization practices, including:

- Service providers are building connected and intelligent supply chain capabilities by analyzing operational requirements and integrating technologies such as predictive analytics, AI, and digital twins to optimize and gain real-time visibility into processes.

- Service providers have also geared up to help manufacturers mitigate risks related to carbon footprints, waste reduction, energy management, pollution management, and green supply chains.

The Bottom Line: Service providers will need to continue to orchestrate smart manufacturing strategies to drive end-to-end digital transformation across the manufacturing operations value chain, striving for efficiency

HFS subscribers can download the report here.

Posted in : HFS Horizons, Manufacturing